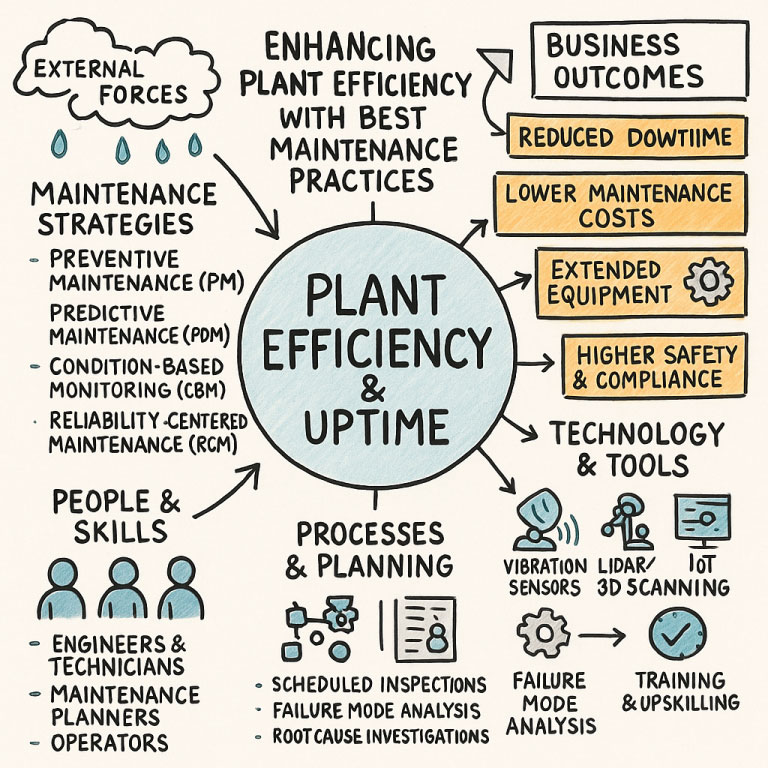

In today’s competitive industrial landscape, maintaining high levels of Overall Equipment Effectiveness (OEE) is a cornerstone of operational success. Achieving this requires adopting advanced maintenance practices that minimize downtime, reduce operational costs, and extend the lifecycle of critical assets.

This white paper outlines best maintenance practices aligned with the ISO 18436.2 standard and highlights how Hamilton By Design’s team of mechanical engineers can partner with your organization to enhance your plant’s OEE. By leveraging our expertise in condition-based and predictive maintenance, we can optimize equipment performance and drive measurable improvements in productivity and reliability.

The Role of Maintenance in Maximizing OEE

OEE is a comprehensive measure of manufacturing productivity, defined by three critical components:

- Availability: Minimizing downtime to maximize operational hours.

- Performance: Ensuring equipment runs at optimal speeds.

- Quality: Reducing defects and waste during production.

Maintenance strategies are key to influencing these factors. Moving beyond reactive approaches to predictive and condition-based maintenance can significantly enhance equipment reliability and efficiency, ensuring better alignment with OEE goals.

Adopting Best Maintenance Practices

Condition-Based Maintenance (CBM)

CBM involves monitoring the real-time condition of equipment to predict and prevent failures. At Hamilton By Design, we integrate cutting-edge technologies like vibration analysis, thermography, and ultrasonic testing to enable proactive interventions before problems escalate.

How CBM Enhances OEE:

- Reduces unplanned downtime (Availability).

- Maintains consistent performance by addressing issues early (Performance).

- Prevents production disruptions that cause defects (Quality).

Predictive Maintenance (PdM)

Predictive maintenance leverages data analytics to anticipate potential failures. By applying ISO 18436.2-certified practices, we implement advanced diagnostic tools and algorithms to forecast maintenance needs with precision.

Our Approach:

- Deploy vibration analysis tools managed by certified Level II and III analysts.

- Use infrared thermography to detect heat anomalies in electrical and mechanical systems.

- Employ ultrasonic testing to identify leaks and structural weaknesses.

Benefits for OEE:

- Prolonged equipment lifespan by addressing issues at their inception.

- Higher productivity with fewer interruptions.

- Reduced maintenance costs through targeted interventions.

Reliability-Centered Maintenance (RCM)

RCM focuses on optimizing maintenance strategies for each asset, emphasizing a deep understanding of failure modes and effects. Our engineers employ RCM to prioritize maintenance tasks that align with your plant’s specific OEE goals.

Steps We Implement:

- Asset Function Analysis: Understanding the purpose and criticality of each asset.

- Failure Mode and Effects Analysis (FMEA): Identifying risks and developing mitigation strategies.

- Data-Driven Decision Making: Using condition monitoring data to guide maintenance schedules.

Impact on OEE:

- Ensures maintenance is aligned with production priorities.

- Reduces waste and rework caused by unexpected equipment malfunctions.

Leveraging ISO 18436.2 Standards

ISO 18436.2 defines the competencies required for condition monitoring personnel, ensuring a standardized approach to predictive maintenance. Hamilton By Design’s mechanical engineers are certified under this standard, offering expertise in:

- Vibration analysis for detecting unbalance, misalignment, and bearing faults.

- Developing and managing comprehensive condition monitoring programs.

- Interpreting and analyzing complex diagnostic data for actionable insights.

How Hamilton By Design Can Assist

Customized Maintenance Solutions

We recognize that every plant has unique operational challenges. Hamilton By Design tailors maintenance strategies to your specific needs, focusing on:

- Asset Criticality Assessment: Identifying and prioritizing key equipment for monitoring and intervention.

- Technology Integration: Implementing IoT-enabled sensors, data platforms, and diagnostic tools.

- Program Development: Designing maintenance schedules aligned with production cycles and OEE targets.

Expert Training and Certification

Our team provides in-depth training for your personnel, ensuring they gain ISO 18436.2 certification and the skills to sustain advanced maintenance programs.

Ongoing Support and Continuous Improvement

Maintenance isn’t static. Hamilton By Design offers ongoing support to refine your maintenance practices, ensuring your plant stays ahead of evolving operational demands.

Case Study: Improving OEE with Hamilton By Design

Challenge: A manufacturing plant experienced frequent equipment failures, leading to a 15% drop in OEE.

Solution: Hamilton By Design implemented a tailored predictive maintenance program:

- Installed vibration sensors on critical rotating machinery.

- Trained plant engineers to monitor and analyze data using ISO 18436.2 standards.

- Provided ongoing diagnostics and recommendations.

Outcome:

- Downtime was reduced by 40%, significantly improving availability.

- Equipment performance stabilized, enhancing productivity.

- Defects decreased by 25%, improving product quality.

Maximizing OEE requires a strategic approach to maintenance that integrates advanced tools, skilled personnel, and data-driven insights. Hamilton By Design’s mechanical engineers, certified under ISO 18436.2, are uniquely equipped to help your plant achieve these goals.

By partnering with us, you can transform your maintenance practices, boost operational efficiency, and secure a competitive edge in your industry. Let Hamilton By Design help you take the first step toward a more reliable and productive future.

WorkTrek – 8 Ways to Improve Your Plant Maintenance

Practical tips for improving maintenance processes, reducing downtime, and boosting productivity.

https://worktrek.com/blog/how-to-improve-plant-maintenance/

Petrochem Expert – Best Practices for Plant Maintenance

Explores how proper maintenance planning ensures efficiency, reliability, and safety in plant operations.

https://petrochemexpert.com/best-practices-for-plant-maintenance-ensuring-operational-efficiency-and-safety/

MaintBoard – Maintenance Planning Strategies

Highlights how scheduling, IoT tools, and predictive approaches improve plant reliability and uptime.

https://maintboard.com/maintenance-planning-strategies

Hamilton By Design – Mechanical Engineering for Mining & Industry

Showcases engineering solutions designed to reduce downtime, improve reliability, and optimize plant performance.

https://www.hamiltonbydesign.com.au/mechanical-engineering-mining-industry-australia/

Hamilton By Design – Drafting & LiDAR / Scanning Services

Describes how accurate scanning and drafting streamline retrofits, reducing errors and saving time during plant upgrades.

https://www.hamiltonbydesign.com.au/services-drafting-lidar-scanning/

Hamilton By Design – Blog: Maximising Uptime at Transfer Points

Focuses on optimising chutes, hoppers, and conveyors to minimise stoppages and keep production flowing.

https://www.hamiltonbydesign.com.au/blog-engineering-insights/