The process of mechanical drafting in Australia has evolved significantly with the advent of advanced technologies such as 3D point cloud scanning tools. These tools allow draftspersons to capture precise measurements of existing physical objects and environments, facilitating more accurate and efficient drafting processes.

In mechanical drafting, the use of 3D point cloud scanning tools enables draftspersons to begin the process by capturing detailed three-dimensional representations of objects, machinery, or structures. This initial step is crucial for accurately documenting existing conditions and incorporating real-world data into the drafting process.

Once the point cloud data is captured, draftspersons use specialized software to process and manipulate the data, converting it into a format that can be used for drafting purposes. This may involve cleaning up noise or outliers in the point cloud, aligning multiple scans to create a unified model, and extracting relevant geometric information for drafting.

Geometric fit and dimensional accuracy are critical aspects of mechanical drafting, particularly when working with point cloud data. Draftspersons must ensure that the drafted components fit precisely within the existing structure or assembly and meet the required tolerances specified by engineering standards and specifications.

Structural strength analysis is another important consideration in mechanical drafting, especially when designing components or structures subjected to mechanical loads or stresses. Draftspersons use finite element analysis (FEA) software to simulate and analyze the structural behavior of mechanical components, ensuring they meet safety and performance requirements.

Availability of materials is a key factor that influences the drafting process. Draftspersons must consider the properties, availability, and cost-effectiveness of materials that comply with Australian standards and meet the project requirements. This may involve researching and sourcing materials that offer the necessary strength, durability, and corrosion resistance for the intended application.

Engineering specifications provide detailed guidelines and requirements for the design and fabrication of mechanical components or systems. Draftspersons must carefully review and interpret these specifications to ensure that the drafted drawings meet all functional, performance, and regulatory requirements specified by the client or project stakeholders.

Client scope plays a significant role in shaping the drafting process. Draftspersons must communicate closely with clients to understand their project goals, preferences, and constraints. This may involve incorporating specific design requirements, customization requests, or aesthetic preferences into the drafting process to ensure that the final drawings meet the client’s expectations.

Time constraints are another factor that influences the mechanical drafting process. Deadlines set by the client or project schedule require draftspersons to work efficiently and prioritize tasks accordingly. This may involve leveraging the capabilities of 3D point cloud scanning tools to streamline data capture and drafting processes, as well as utilizing CAD software features to automate repetitive tasks and improve productivity.

The draftsperson’s style and expertise also play a crucial role in the drafting process. Experienced draftspersons bring a wealth of knowledge, problem-solving skills, and attention to detail to the drafting process, ensuring that the final drawings are accurate, comprehensive, and compliant with industry standards and specifications.

ISO standards provide guidelines for drafting practices, terminology, and quality management systems. Draftspersons must adhere to ISO standards to ensure consistency, compatibility, and interoperability between engineering drawings and documentation across different countries and industries.

In summary, the process of mechanical drafting in Australia involves leveraging advanced technologies such as 3D point cloud scanning tools, adhering to engineering standards and specifications, considering client requirements and time constraints, and applying the draftsperson’s expertise to create accurate and comprehensive drawings that meet the needs of the project. By following established procedures and incorporating innovative technologies, mechanical draftspersons play a crucial role in the design and fabrication of mechanical components and systems.

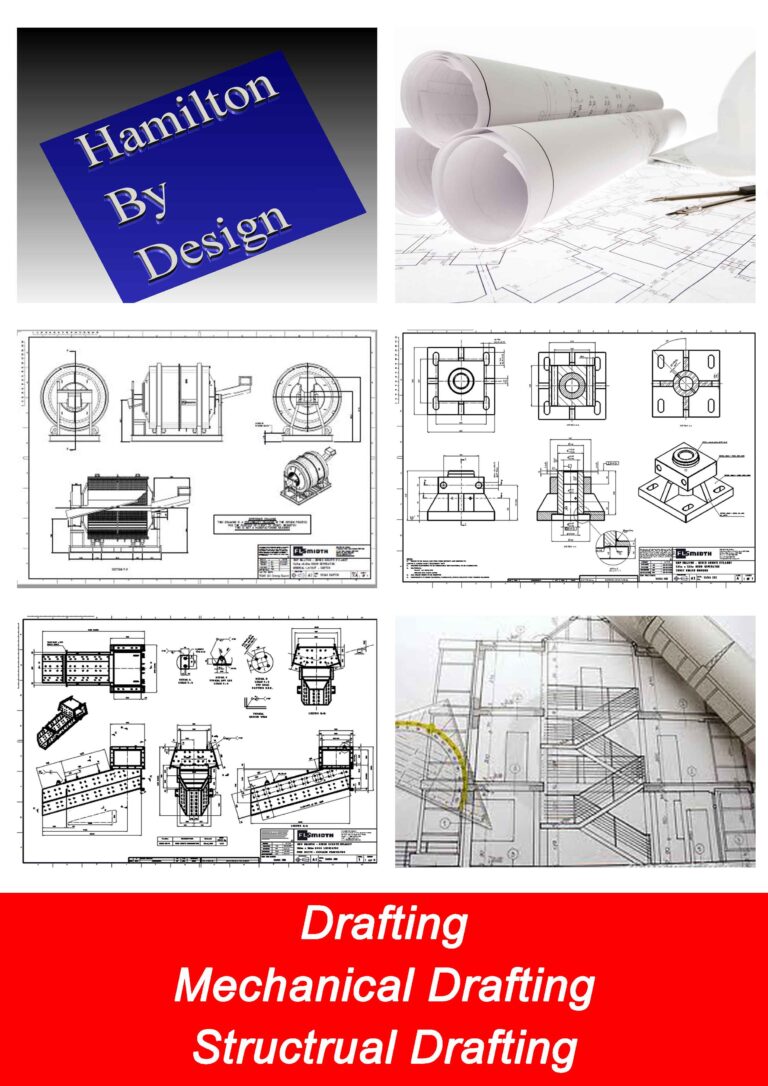

Mechanical Engineering | Structural Engineering

Mechanical Drafting | Structural Drafting

3D CAD Modelling | 3D Scanning